Ladle Crane Safety: How Ladle Hook Tracking System Ensure Safety

Ladle Hook Tracking System boosts safety, precision & efficiency, reducing human error in steel mill crane operation. Get safe ladle hook tracking system.

Importance of Safety in Steel Mills

Steel mills are inherently high-risk environments. The handling of molten metal and heavy loads requires strict safety measures to protect workers and equipment. One small mistake can lead to catastrophic consequences. That's why safety is the top priority in these facilities.

- High-Risk Operations: Molten metal can reach extreme temperatures, and heavy machinery is in constant use.

- Strict Safety Protocols: To prevent accidents, mills follow rigorous safety standards.

- Consequences of Neglecting Safety: Mishaps can cause injuries, equipment damage, and production halts.

Every worker in the mill must follow safety rules. Failure to do so could result in severe consequences. That's why advanced safety systems are essential for steel mill operations.

The Role of Ladle Cranes

Ladle cranes are crucial to the operation of steel mills. These cranes lift and move molten steel, one of the most dangerous substances to handle. The accuracy and safety of ladle cranes directly affect the efficiency and safety of the entire production process.

- Handling Molten Metal: Ladle cranes are designed to carry heavy, molten steel safely.

- Key to Efficient Production: The smooth operation of ladle cranes ensures continuous steel production.

- Need for Precision: Even the smallest mistake can cause accidents, making precision in crane operation vital.

Ladle cranes make steel production possible. But because of the high risks involved, their operation must be precise and safe at all times.

Introduction to the Ladle Hook Tracking System

The Ladle Hook Tracking System is a modern solution designed to improve the safety and efficiency of ladle cranes. It uses advanced AI algorithms to track the crane hook's movements and position. This technology helps to prevent human errors, ensuring that the hook is always in the right place.

- AI-Powered Tracking: The system uses AI to monitor the hook's location in real-time.

- Reduces Human Error: It decreases the chance of mistakes caused by fatigue, distractions, or lack of visibility.

- Increases Precision: The system ensures that the hook is always accurately positioned, reducing the risk of accidents.

With the Ladle Hook Tracking System, steel mills can operate more safely and efficiently. This system makes crane operations more reliable, reducing risks and improving the overall production process.

The Ladle Crane and Hook Tracking System: Key Components

What is a Ladle Crane?

Ladle cranes are specialized cranes used in steel mills for handling molten steel. They are essential for lifting and transporting ladles, which are large containers filled with molten metal. The cranes are designed with safety in mind, as they deal with extremely hazardous materials.

- Function: Ladle cranes lift and move molten steel from one part of the mill to another.

- Safety Features: They are equipped with various safety systems to prevent accidents, including emergency stops, overload sensors, and anti-sway controls.

- Precision Required: These cranes must be extremely precise when handling molten steel, as any mistake could result in spills or accidents.

Ladle cranes are vital to steel mill operations, but their complex and risky tasks demand high levels of safety and precision.

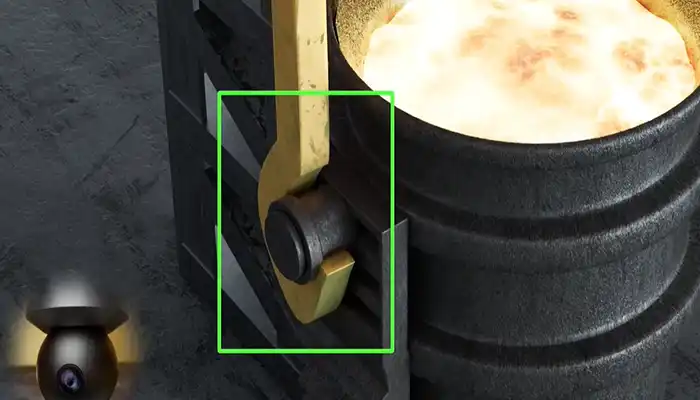

Crane Lifting Hook Visual Tracking and Hanging Position Confirmation System

The Crane Lifting Hook Visual Tracking and Hanging Position Confirmation System is an advanced feature that enhances safety and accuracy in ladle crane operations. It relies on AI-powered technology to monitor the crane hook's position and hanging status. This system provides operators with real-time, accurate feedback on the crane's movements, reducing the risk of errors.

AI-Powered Visual Tracking

The system continuously tracks the crane's lifting hook using AI algorithms. By monitoring the hook's movements and hanging position, it ensures that operators receive accurate data on its current status.

- Continuous Monitoring: The AI tracks the hook's position in real-time.

- Accurate Data: The system provides precise feedback to the operator, eliminating guesswork.

- Reduces Human Error: With automated tracking, the risk of mistakes caused by human limitations (like fatigue) is minimized.

This feature allows operators to make better decisions and ensures that the crane operates safely.

Automatic Focal Length Adjustment

The system automatically adjusts the camera's focal length, keeping the crane hook and its lug in clear view at all times. This ensures that the operator has a clear line of sight regardless of the crane's height or distance.

- Always in Focus: The system zooms in or out based on the hook's position.

- Enhanced Visibility: Even at high driving heights, the hook remains clearly visible.

- No Manual Adjustment: Operators don't have to worry about manually adjusting the camera to focus on the hook.

This automatic adjustment helps operators maintain constant visual control over the hook's position, increasing operational safety.

Stable Screen Adjustment

The system ensures that the screen's focal length is adjusted gradually. This prevents sudden zoom-ins or zoom-outs that could distract the operator or make the image unclear.

- Gradual Adjustments: The focal length changes are smooth and moderate.

- Prevents Distractions: The operator isn't overwhelmed by constant or erratic changes in the image.

- Clear Visuals: This steady adjustment helps the operator maintain focus on the hook without losing sight of crucial details.

Stable screen adjustments allow the operator to work with clear, uninterrupted visuals, enhancing safety and efficiency in crane operations.

Addressing Human Error in Steel Mill Operations

Common Risks and Errors

Steel mill operations are fast-paced and intense, which increases the chances of human error. Operators are often under pressure to move heavy loads quickly, and this environment can lead to various risks. Some common factors contributing to mistakes include:

- Fatigue: Long hours and demanding work conditions can lead to tiredness, affecting focus and reaction time.

- Distractions: The noisy and busy environment of a steel mill can make it difficult for operators to concentrate. Even small distractions can result in critical mistakes.

- Miscommunication: With many people involved in the process, poor communication between team members can cause confusion about load positioning or crane movements.

These errors can result in mispositioned hooks, improper load handling, or even overloading the crane, all of which could lead to dangerous accidents or equipment damage.

The High-Stakes Nature of Steel Production

Steel production involves working with molten metal, which is extremely hot and dangerous. The stakes are high in every move made by the crane, as any mistake can result in serious consequences. Here's why precision is vital:

- Handling Molten Metal: Molten steel can reach temperatures of over 1,500°C, which can cause fatal burns if there's an accident. The ability to position the crane hook with accuracy is crucial to avoid spills or accidents.

- Heavy Loads: Ladle cranes carry massive, heavy loads, and even the smallest miscalculation can cause damage to both the crane and the ladle.

- Risks of Human Error: In this high-pressure environment, human error becomes even riskier. Fatigue or lapses in judgment can cause the crane to mishandle heavy or unstable loads, increasing the potential for accidents.

Given the dangers involved in steel production, relying solely on human judgment is not enough. Technology, like the Ladle Hook Tracking System, helps minimize these risks by offering real-time tracking, clear visual feedback, and automated adjustments. This technology plays a key role in reducing human error and improving the overall safety of steel mill operations.

How the Ladle Hook Tracking System Enhances Safety

Real-Time Tracking and Monitoring

AI Algorithms for Precise Positioning

The Ladle Hook Tracking System uses advanced AI algorithms to track the crane's lifting hook in real-time. The system continuously monitors the hook's position, ensuring that it is always accurately placed. This allows the operator to make precise adjustments, reducing the risk of mistakes during crane operation.

- Continuous Monitoring: The system provides real-time updates on the hook's location.

- Precision: Operators can trust that the hook is exactly where it needs to be, enhancing overall safety.

By relying on AI, the system reduces the chance of human error, helping ensure the crane's operation remains safe and precise at all times.

Adaptive Zoom Technology

One of the standout features of the Ladle Hook Tracking System is its adaptive zoom functionality. This technology automatically adjusts the camera's zoom to maintain a clear view of the hook, even from high up or at long distances.

- Automatic Adjustments: The system zooms in or out as needed, ensuring clear visibility of the hook.

- No Manual Effort: Operators no longer need to adjust the camera focus manually, freeing them from unnecessary distractions.

This ensures that operators can focus on the task at hand, without losing sight of critical details, improving both safety and efficiency.

Reducing Operator Reliance on Visual Observation

By automating many of the visual aspects of crane operation, the Ladle Hook Tracking System helps reduce the burden on operators. Manual focus adjustments are no longer needed, and the system provides automatic visual updates.

- Improved Situational Awareness: The system ensures the operator always has a clear view of the hook without manual interference.

- Fewer Distractions: With automatic adjustments, operators can stay focused on the crane's operation, reducing the risk of errors caused by distractions or fatigue.

This reduction in manual adjustments allows operators to better assess the situation and make quicker, safer decisions.

Hook Hanging Position Confirmation Algorithm

Position and Stability Judgments

The system's AI algorithms continuously evaluate whether the hook is correctly positioned on the lug. As the hook approaches the lug, the system assesses if it is stable and securely hooked.

- Real-Time Feedback: The system provides ongoing stability assessments.

- Accurate Judgment: When the hook is nearing its final position, the system confirms whether it is properly secured, reducing the chance of misplacement or instability.

This feature helps operators make informed decisions about load stability, improving safety during the lifting process.

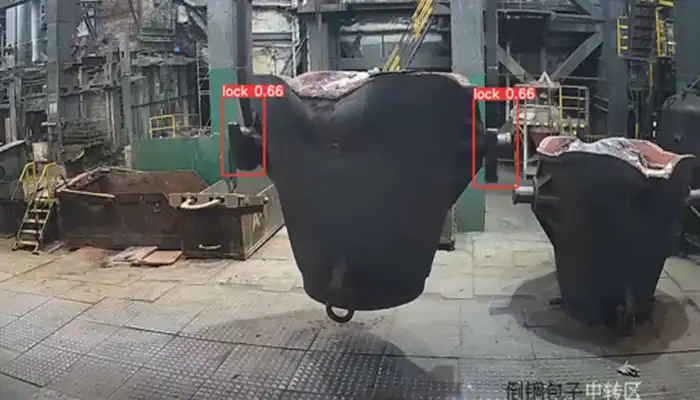

Visual Decision-Making Support

The system provides operators with visual confirmation on the screen, indicating whether the hook is in the correct position. This decision-making support gives operators a clear, objective basis for determining if the load is stable.

- Clear Indicators: The visual display clearly shows the operator whether the hook is securely in place.

- Enhanced Decision-Making: With this confirmation, the operator can make more informed, safer decisions regarding the load's position and stability.

By relying on visual feedback, operators can work with greater confidence, reducing risks and improving safety.

Preventing Overloading and Equipment Damage

The system also plays a key role in protecting both the crane and the ladle from damage. It constantly monitors the load and the crane's capacity, providing alerts when the crane is close to exceeding its safe limit.

- Load Monitoring: The system tracks the weight of the load to ensure it doesn't exceed the crane's capacity.

- Overload Alerts: If the load is too heavy or improperly balanced, the system will warn the operator.

These alerts prevent overloading, which could otherwise damage the crane or cause accidents. It helps keep both the crane and the ladle intact, ensuring long-term durability and safety.

Adaptation to Harsh Environments

Steel mills are often challenging environments, with factors like high temperatures, smoke, and bright flames that can impair visibility. The Ladle Hook Tracking System is built to handle these tough conditions.

- Environmental Adaptability: The system is designed to recognize and adjust to phenomena such as high brightness, smoke, or flames.

- Uninterrupted Operation: It ensures that the crane operates safely, even when visibility is poor due to environmental factors.

This feature allows the system to maintain visibility and functionality under extreme conditions, which is crucial in the unpredictable environment of a steel mill. It ensures the safety of both the operator and the equipment, no matter the circumstances.

Expandable Applications

Ground Cameras for Enhanced Visibility

In large steel mills, visibility can often be limited from the operator's viewpoint. To address this, ground cameras can be integrated into the Ladle Hook Tracking System to offer a broader perspective of the crane's movements. These cameras provide additional angles, helping operators confirm the stability of the load and ensuring greater safety.

- Wider Coverage: Ground cameras offer a full view of the crane's movements from the ground level, which may not be visible from the operator's position in the crane.

- Clearer Feedback: When combined with stability confirmation algorithms, these cameras provide more accurate and reliable information, enhancing the operator's ability to assess the situation in real-time.

- Improved Safety: The extra views make it easier to detect potential risks or stability issues before they become problems, improving the safety of operations.

By expanding visibility beyond the crane operator's direct line of sight, ground cameras help ensure that the crane is operating smoothly and safely.

Flexibility for Various Factory Needs

One of the key advantages of the Ladle Hook Tracking System is its flexibility. The system can be easily customized to fit the unique needs of different factories, adapting to various operational requirements.

- Customizable Setup: The system can be tailored with additional cameras, sensors, and other features to meet the specific needs of each steel mill.

- Expandable: Whether you need more views or enhanced capabilities, the system can grow with the factory's requirements, ensuring that safety and efficiency are always prioritized.

- Adaptable to Different Layouts: The system can be configured to handle different plant layouts, ensuring that every corner of the facility is covered.

This level of adaptability makes the Ladle Hook Tracking System a valuable tool for any steel mill, no matter the size or complexity of the operation. It ensures that the system can evolve along with the factory's needs, maintaining high safety standards and operational efficiency.

Applications

Examples from Steel Mills

Steel mills that have implemented the Ladle Hook Tracking System have seen significant improvements in safety and efficiency. The system has been particularly effective in reducing operational risks, such as mispositioned hooks, overloading, and accidents caused by human error.

- Reduced Operational Risks: Mills have reported fewer incidents involving misalignment or improper handling of molten metal. The AI algorithms ensure that the crane hook is positioned accurately every time, which helps avoid dangerous mistakes.

- Improved Safety Metrics: Safety statistics have improved, with fewer accidents and injuries reported due to the enhanced precision and real-time tracking provided by the system.

- Increased Efficiency: The ability to track the crane hook in real-time has streamlined operations, allowing for faster and more efficient movement of molten metal while maintaining high safety standards.

Overall, the Ladle Hook Tracking System has proven to be a game-changer in steel mills, helping them operate more safely and efficiently.

Feedback from Operators and Managers

Operators' Perspective

Operators appreciate the Ladle Hook Tracking System because it reduces their reliance on visual observation. With the automatic focal length adjustments and stability confirmations, they no longer have to manually adjust the camera focus or constantly monitor the hook's position, which reduces distractions and fatigue.

- Easier Monitoring: Operators can focus on the overall crane operation without worrying about losing track of the hook's position.

- Less Fatigue: By automating many of the visual aspects, operators experience less mental strain, allowing them to work more efficiently and safely.

Safety Managers' Perspective

Safety managers report a significant decrease in accidents and incidents since the system's implementation. With real-time tracking and stability checks, operators can make more informed decisions, ensuring that the crane is always operating within its safe limits.

- Fewer Incidents: With better monitoring and decision-making support, safety managers have seen fewer mishaps in the steel mill.

- Enhanced Precision: The system's ability to monitor the hook's position and load stability has increased overall operational precision, making it easier to maintain safety standards.

The system's contributions to both operator ease and safety performance have made it a valuable asset for steel mills looking to improve their operations.

The Ladle Hook Tracking System offers a reliable and intelligent approach to enhancing safety in steel mills. By integrating AI-driven algorithms, it:

- Improves Precision: The system ensures that crane hooks are accurately positioned every time, minimizing the risk of errors during molten metal handling.

- Reduces Human Error: With real-time tracking, automatic adjustments, and stability checks, the system minimizes the chances of mistakes caused by operator fatigue or distractions.

- Supports Informed Decision-Making: Operators receive real-time data and visual feedback, allowing them to make safer, more precise decisions during crane operation.

These features not only improve safety but also streamline operations, contributing to overall productivity.

Long-Term Impact on Steel Mill Safety

The implementation of advanced technologies like the Ladle Hook Tracking System is crucial for long-term safety improvements in steel mills. By leveraging AI and automation, steel mills can:

- Significantly Improve Worker Safety: Reduced human error and enhanced operational precision lead to fewer accidents, creating a safer working environment.

- Minimize Operational Risks: The system helps prevent common risks like overloading and mispositioning, which can cause equipment damage and unsafe situations.

- Increase Efficiency: With improved safety comes improved operational flow, helping mills run more smoothly and efficiently over time.

As steel mills continue to adopt these advanced technologies, the impact on safety and efficiency will become even more significant.

The future of crane operations in steel mills is heavily tied to automation and AI. As technology continues to advance, we can expect:

- Greater Integration of Automation: More tasks will be automated, reducing the potential for human error and enhancing the overall safety of crane operations.

- AI-Driven Safety Systems: AI will continue to improve the precision of crane operations, from tracking the hook to monitoring load stability, ensuring the safety of workers and equipment.

- Increased Adoption of Smart Technology: As steel mills evolve, adopting more AI-powered systems will be key to maintaining high safety standards while improving productivity.

In conclusion, the Ladle Hook Tracking System is an important step toward a safer and more efficient future for steel mills. The continued integration of advanced technologies will transform crane operations and help shape the next generation of steel mill safety practices.